The final report “Biofuels for the marine shipping sector”, published by IEA Bioenergy in October 2017, addresses the potential of biofuels in maritime transport by performing a technical assessment of biofuels for marine engines, taking into account the entire supply chain from field to ship.

As one of the major worlds means of transportation, maritime transport consumes hundreds of Mt of fuel a year and accounts for 2-3% of CO2, 4-9% SOX and 10-15% of NOx global emissions. The main fuels used by big vessels are Heavy Fuel Oil (HFO) and Marine Diesel Oil (MDO), that are a less-refined type of fuel (i.e. it has a high viscosity and a high sulphur level), with severe effects on air and water pollution.

Due to this, IMO (International Marine Organization) has tightened regulation measures of fuel sulphur level by establishing Emission Control Areas (ECAs) in coastal waters around the globe where only 0.1% of fuel sulphur is tolerated. By 2020 no ships will be allowed to sail elsewhere if using a fuel with more than 0.5% percentage of sulphur. The introduction of the Energy Efficiency Design Index (EEDI) for ships built from 2013 and the Ship Energy Efficiency Management Plan (SEEMP) for all ships above 400 GT, as well as the creation of guidelines for the voluntary use of the Energy Efficiency Operational Indicator (EEOI), follow this trend. Therefore, low-sulphur fuels or scrubbers are needed to ensure SOX reduction.

A feasible alternative to unrefined fuels may be provided by Very low Sulphur Fuel Oil (VLSFO), with a sulphur content from 0.1% to 0.5%, and by Ultralow Sulphur Oil (ULSFO), with less than 0.1% sulphur percentage. A large increase in CO2 emissions because of more refining, however, is generated. Liquefied natural gas (LNG) can be another solution, but it would request a refitting of the engines and the installation of pressurized fuel storage onboard, with a marked peak in general costs. Other fuels such as methanol are used in a smaller degree because of under-developed supply infrastructure.

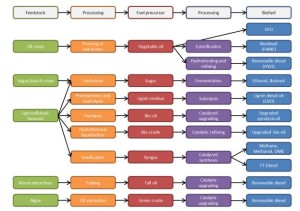

both conventional and advanced biofuels. Source: IEA Bioenergy

To this extent, biofuels may represent the best option to reduce SOX and CO2 emissions, with due regard of several aspects.

By now, current renewable diesel is mainly produced by plant-based oils or e.g. used oil cooking oil (UCO), but biofuels production is needed to meet the average merchant maritime sector consumption and to be located near major ports or bunker stations.

Bioethanol is produced in large quantities, but it is not compatible with contemporary shipping engines and it cannot be used as a drop-in fuel: the development of multifuel engines could solve this kind of issue.

High short-term costs may be overcome in the long run thanks to more stringent anti-pollution standards related to Greenhouse gases (GHG) release and due to support measures, such as carbon taxes and subsidies, alongside with further technological development. In addition to that, an increase or a stable maintenance of oil prices at current level would incentive biofuels production.

The development of biofuels compatible with marine engines is still at early stage, but the first-generation bioethanol and biodiesel industries have already been established and cost-competitive 2nd generation biofuels areslowly becoming a concrete option. Short sea shipping sector, with fixed routes and high shipping activity, could be the first step towards biofuels supply evolution. Pioneers such as large freight shipping companies, ferry and cruise companies could lead this transition.

Some experts estimate that biofuels could provide from 5 to 10% for the global marine fuel mix by 2030 (about 16-33 million tons of biofuel).

This post by Chiara Pappalardo is based on “Biofuels for the Marine Shipping Sector” by IEA Bioenergy – Task 39.

To read the full report, please click here.