Biomass residues and such as agro-industrial waste or sewage sludge are a viable resource to produce energy,

fuels and chemicals. They are abundant and generally low-cost, but converting these feedstocks into marketable products can be a challenging task due to their heterogeneous nature.

A promising technology to do this, is the TCR® system (Thermo-Catalytic Reforming) developed by Fraunhofer UMSICHT in Germany. This system is based on the combination of the intermediate pyrolysis of biomass with a reforming stage. Pyrolysis is a thermochemical process through which different biomass feedstocks can be processed into liquids, gaseous and solids fuels, in variable parts depending on temperature, heating rate and other process conditions. Normally the physical and chemical properties of the bio-liquids and the syngas as such are not suitable for long term use in internal combustion engines. In the TCR® system pyrolysis vapours are treated in a reforming reactor and converted into hydrogen-rich syngas and an organic biphasic liquid (bio-oil and aqueous phase). The quality of the TCR-oil and TCR-gases are suitable for use in engines for long-term usage such as combined heat and power production. A solid char product is also obtained, which could be used as soil amendant.

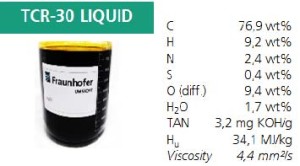

A 30kg/h TCR® plant is installed in Sulzbach-Rosenberg. At this site, Fraunhofer researchers have successfully converted sewage sludge from a wastewater treatment plant into bio-oil and syngas, whose quality is suitable for use in engines for combined heat and power production. The quantity of the bio-oil and of the syngas obtained amounted to less than 30% of the original mass of the feedstock, but still had 60% of its initial energy content. In terms of quality, the bio-oil showed very high lower heating value compared to conventional flash pyrolysis oil (34 MJ/kg versus 16 MJ/kg of conventional flash pyrolysis oil), low viscosity, low oxygen content and total acid number (TAN) simliar to conventional diesel. These are important parameters for engine durability. The TCR®-oil also showed good thermal stability, another essential characteristic for use in CHP. Both the oil and the syngas were tested in a modified dual-fuel engine (20kWel), in different blends with biodiesel.

The performance of the engine was measured at different loads. TCR®-oil blends at 50% with biodiesel showed similar ignition behaviour to tests conducted with pure biodiesel and the addition of TCR-gas even improved the ignition behaviour of TCR®-oil biodiesel blends.

This post is based on the paper “Combined Heat and Power Generation from Solid Biomass Derived Bioliquids and Syngas by TCR®” by Andreas Apfelbacher et al., presented at the 24th European Biomass Conference and Exhibition.