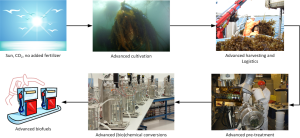

MacroFuels H2020 project aims to develop technologies to produce advanced liquid biofuels from seaweed for transportation, i.e. aviation, cargo and truck fuels.

MacroFuels specific objectives are: to improve the production of ethanol and ABE (Acetone, Butanol and Ethanol), to evaluate the thermochemical conversion of algal sugars (i.e. xylose) into furans and to assess the economic viability of such pathways, by providing data to optimise commercial implementation.

Within the context of the project, ECN (Energy research Centre of the Netherlands) part of TNO developed economic models to identify the major cost drivers of seaweed to biofuels pathways by targeting biofuels such as ethanol, butanol and furanics, as well as biogas.

To meet the target of 60% reduction of GHG by 2050 in the European Union, research findings showed the need for a large-scale production of biofuels out of seaweed. For sufficient economy of scale and impact, a seaweed biorefinery needs to meet the same biofuels production levels as an ethanol biorefinery like the Abengoa bioethanol plant in Rotterdam (with a capacity of 480 ktons/yr from 1.2 MT of grain) producing 3% of the motor fuel use in The Netherlands (2014, CBS). To obtain 1.2 Mton of seaweed (dry weight), hundreds of marine km2 are needed to cultivate seaweeds.

Based on these data, ECN suggested an “economy of repetition”, that is: dedicated production lines for parts, specific deployment equipment as well as seeding/harvesting equipment. Furthermore, ECN developed a techno/economic evaluation of a biorefinery design on the basis of a screening study for Laminaria digitata aiming at seaweed fractionation products such as sugars and alginate, and develops a conceptual design for producing ethanol and ABE from Saccharina latissima.. These studies take into account the cultivation cost and the optimal harvesting period. . The most important installed costs for a Laminaria digitate biorefinery are due to storage and laminarin separation; on the other hand, the best revenues derive from the sale of mannitol (19%) and alginate (57%).

This post is based on The Cost Drivers of Seaweed Based Fuel Production by Dijkstra J.W., van Hal J.W. and Bjerre A-B., presented at the 26th European Biomass Conference & Exhibition. The full presentation is available open access in the official proceedings of the conference.