![]()

Did you know that it is possible to convert bio waste residues into a new generation of biofuels to be used for road transport? This is the aim of an EU H2020 project called Biofuels from WASTE TO ROAD transport (WASTE2ROAD), which has started in October 2018 and will run for 4 years.

Objectives and main activities of the project

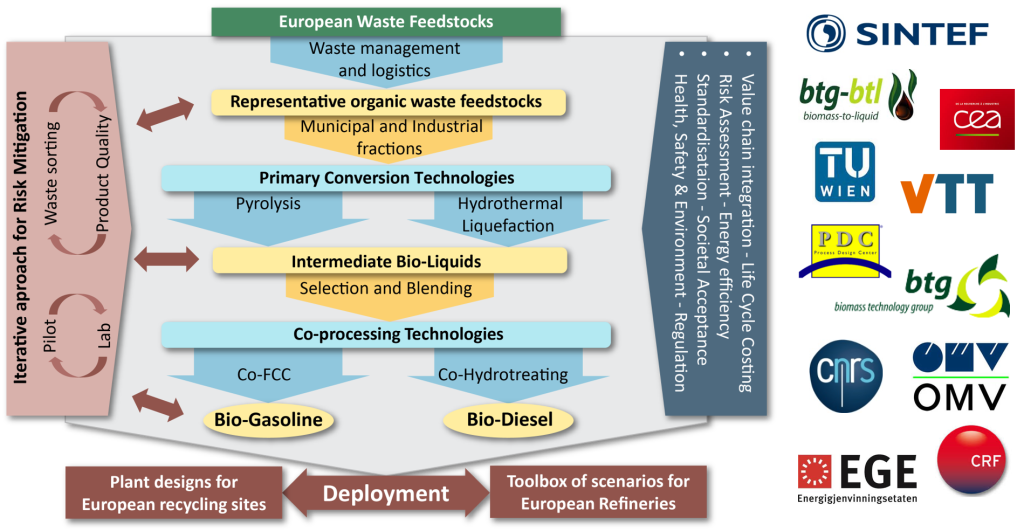

The WASTE2ROAD project aims to develop a new generation of cost-effective biofuels from a selected range of low cost and abundant biogenic residues and waste fractions. This will be achieved through optimisation of European waste recycling logistics and development of efficient conversion technologies, giving carbon yields > 45% with greenhouse gases (GHG) savings > 80% from conversion of feedstocks from the approximate 220 M tons unrecycled waste streams. The consortium, covering the full value chain from waste collection and recycling via co-refining through to road transport, will deploy risk-mitigation pathways to realise industrial implementation, with primary processing at European waste recycling sites and co-processing within European refineries, yielding a potential demonstration unit achieving up to 40,000 tpa within 2022.

Management of biogenic residues and waste (including sorting and pre-treatment strategies) is a strong focus in the project, to allow a subsequent transformation of a diverse range of waste (and fractions thereof) into intermediate bio-liquids, deploying both fast pyrolysis (‘pyrolysis’) and hydrothermal liquefaction (‘HTL’). Production of advanced biofuels will then be enabled through intermediate refining processes (fractionation, stabilisation) combined with existing downstream refinery co-processing technologies, more specifically co-Fluid Catalytic Cracking (‘co-FCC’) and co-hydrotreating/hydrocracking (‘co-HT’), both at different levels of severities (temperatures, hydrogen consumption, carbon yield). Products to be used for road transport are aimed at gasoline and diesel with assessment of final end-use compatibility.

The project will bring these technologies from today’s TRL3-4 up to TRL5, through the validation in a relevant refinery environment. The project will establish correlations between biofuel’s properties (as determined in standards for transportation fuels, especially road), the quality and properties of diverse renewable biogenic waste fractions (process, acidity, water, charring tendency, contaminants such as plastics residues etc.) and all relevant process parameters along the whole value chain, including sustainable hydrogen production. The study of these combinations will allow a unique understanding, correlating the influence of the nature and diversity of feedstock, and conditioning processes on the final products quality. This understanding will provide insight into synergetic effects, to permit a robust and reliable sustainability assessment of the environmental (in terms of GHG performance), and economic and social benefits with respect to current technologies. Specific attention will be paid to risk management (supply, logistics, technical, economic, business), with dedicated tasks throughout the project. Connection with relevant standardisation bodies will be established during the course of the project, as well as communication with the relevant stakeholders to ensure the future exploitation of the project’s results.

Technologies within WASTE2ROAD

The technologies that are being investigated in WASTE2ROAD aim to establish the basis for production of advanced biofuels through integration with existing chemical and refinery installations, using the refinery expertise of the European refiners to benchmark and validate the results. The product of the project will be a toolbox allowing European refineries to assess the viability of integrating the most optimal value chains based on their regional waste-based biogenic resources. This makes the focus of WASTE2ROAD relevant and replicable across refineries, both within and outside Europe.

Currently there is a slow deployment of technologies to produce biofuels within Europe. The integration of the biomass/waste-based feedstocks conversion value chains into existing refinery and chemical installations is a new market that can realise a significant step change. The involvement of refinery operators in the project aims to demonstrate the viability of this approach allowing options for co-location and integration of biofuels production within a refinery.

The development of new value chains from waste-based feedstocks to products from existing refineries will need the establishment of a number of new specifications in addition to extensive costs and sustainability evaluations. WASTE2ROAD will be engaging in evaluating the viability of the biofuels for end use in existing engines, in addition to the specifications required by refineries for integrating of intermediate bio-oils into different entry points in existing refineries.

Key targets include:

- Reduction of supply costs by 25 %

- Increase of overall carbon yield to > 45 %

- GHG savings > 80 % compared to fossil fuels

- Percentage of bio-liquids in product 5-20 % (for co-FCC) and > 10 % (for co-HT)

- Residual oxygen content in product < 0.5 wt%

- Increase of overall process efficiency along the value chain

- Development of at least four value chains for commercial application

- Minimum Fuel Selling Price (MFSP) < 1.0 €/L

- Pilot-testing at TRL 5

Discover more about WASTE2ROAD at the upcoming HTL workshop

HTL is one of the core conversion technologies investigated in WASTE2ROAD, used primarily for bio-crude production from wet biogenic feedstocks. The project will contribute to further development of the HTL technology towards industrial implementation, through testing various types of feedstocks (e.g., black liquor, food waste) and establishing correlations between the composition of the feedstocks, the process design and operational parameters and the resulting properties of the bio-crude.

WASTE2ROAD cooperates with other EU H2020 biofuel projects and will also participate at the Expert Workshop: Potential of Hydrothermal Liquefaction (HTL) routes for biofuel production on November 19th, 2019 in Brussels that will bring together stakeholders from science and industry working on implementation and commercialization of HTL. The partners will illustrate the status of the current activities and the prospects for industrial uptake of the processes. Signup for the workshop and join us in Brussels.

Funding and Consortium

WASTE2ROAD is funded by the European Union’s Horizon 2020 research and innovation programme under the grant agreement No 818120.

WASTE2ROAD is funded by the European Union’s Horizon 2020 research and innovation programme under the grant agreement No 818120.

The project’s consortium involves 11 partners from Norway, Finland, France, Netherlands, Austria and Italy. SINTEF is the coordinator and other partners include: French National Center for Scientific Research (CNRS), BTG Biomass Technology Group BV (BTG), VTT Technical Research Centre of Finland, Process Design Center BV (PDC), BTG Bioliquids (BTL), Vienna University of Technology (TUW), OMV Refining and Marketing, French Alternative Energies and Atomic Energy Agency (CEA), Norwegian Waste Management Agency (EGE) and the Research Center Fiat (CRF).

Contacts and Information

For more information, please visit the WASTE2ROAD website or contact us by email:

Project coordinator: Duncan Akporiaye Duncan.Akporiaye@sintef.no

Project manager: Jana Chladek Jana.Chladek@sintef.no

Text by Duncan Akporiaye, WASTE2ROAD Project coordinator