Supplying 300.000 tons of straw for a large bioethanol plant might be a game changer for the Danish straw market, competing with straw combustion for power production and future use of straw for biogas. In addition, such an amount requires comprehensive logistic considerations and due economic and environmental calculations. These challenges are addressed by a project for the development of mobile straw briquetting units, named “Straw Logistics for Bioethanol and Biogas“. The project is carried out by a consortium of Danish organizations led by Agrobusiness Park and is supported by Central Denmark Region.

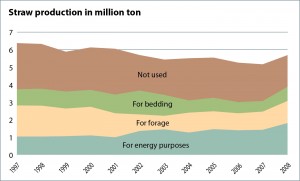

Current and planned use of straw in Denmark

Denmark produces around 6 million tons of cereal straw every year, roughly 1/3 of which is used for bedding and forage for animals, 1/3 is used for energy purposes (combustion) and 1/3 is left for soil incorporation. Burning straw for energy has developed during the last 30 years and nowadays provides annually roughly 20 PJ of energy in form of heat and electricity. Straw combustion is challenged by the fact that a part of it is being replaced by wood pellets which are easier to handle in large scale power plants.

However innovative solutions are paving the way for alternative emerging markets for straw. In 2013, a straw based bioethanol plant has started operation in Northern Italy. Also, a Danish consortium is planning a large bioethanol plant based on straw in Holstebro, Denmark. The expected intake here is around 300.000 tons of straw. Advanced biofuels is a part of the 2020 goals of EU and straw is indeed an interesting feedstock.

Recently, the idea of pretreating straw for biogas has been developed and a promising technology is briquetting. The simple process of briquetting ‘pretreats’ the straw to become soluble in the manure based biogas plants and the gas production is quite impressive. Approximately 400 m3 biogas (or around 250 m3 methane) can be produced per tons of straw briquettes. In addition, straw for biogas still returns a part of the straw carbon to the soils via the biogas digestate. The Danish straw market is challenged by new opportunities and if straw becomes easier to mobilize, these opportunities could be further explored.

The logistical model concept for alternatives

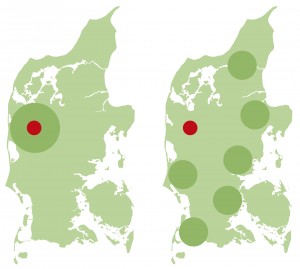

Måbjerg Energy Concept (a full-scale integrated biorefinery that is planned by 2017 in Holstebro, a rural area in Jutland) is expected to need an intake of 300.000 tons of straw (wheat, barley). This amount of straw is available within 100 km radius from the locality in most years based on historical data. However, standard transport of bales (500 kg/bales, 12 tons/transport) will result in approximately 25.000 yearly transports. This specific challenge needs to be explored and alternatives are needed to reduce the transportation costs and heavy traffic near the plant.

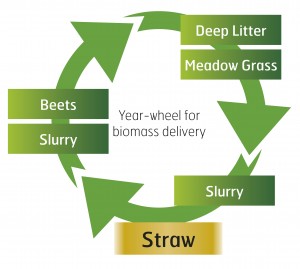

For this reason straw resources are considered in a more generalized model including some of the most important biomass resources in Denmark: straw, meadow grass, beets, slurry and deep litter, including geographical location of the production (resource mapping). The focus area of this project is in Central Denmark region with approximately 1/3 of Danish agricultural production, acknowledging that biomass follows market forces rather than administrative boundaries. The model can be used for resource planning and decision making when new plants will need biomass feedstock, or when existing plants will search for new types of biomass. Which parameters should be included in this decision making process?

Scenarios for decision makers

A ‘Year-wheel’ model was developed to identify the different types of biomass available all year round, including different storage alternatives influencing quality, costs etc. The ‘Year-wheel’ model is combined with a value chain analysis tool, which considers amount, biomass quality, CO2 emission, costs etc. to analyze a series of consequential scenarios for improved decision making.

The tools developed should enable the plant owner to analyze different feedstock alternatives. This could be in the planning phase of a new plant (e.g. biogas, bioethanol): which types of biomass are available in the area throughout the year, which alternative pretreatments can be considered, what cost and CO2 emission. The model can also be useful for considering alternative biomass supply chains for an existing plant.

The Year-Wheel model has been applied to the Maabjerg Energy Concept; traditional baling of straw and transport to the plant was compared to decentralized briquetting of the straw in terms of capacity, economy, quality etc. Briquetting requires dry straw (8-14% water) from the fields and storage capacity can be reduced to less than 50%. Transport capacity can be increased from 12 up to 33 tons per transport.

This increased flexibility is analyzed in terms of logistics, costs, CO2 emissions etc. One possible outcome is that baled straw is the optimal solution for local suppliers around MEC in Holstebro shortly after harvest. A sufficient supply of high-quality briquettes will be assured throughout the year by satellite briquetting plants.

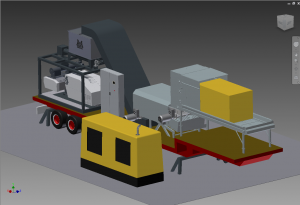

Briquetting straw for biogas

Additionally the potential of straw briquetting for biogas production is being analyzed. In order to use straw for small or large scale biogas production a briquetting process is needed. The next step in the project is therefore to develop and demonstrate a mobile unit that can convert straw bales into briquettes directly at the farm/the straw storage facility, thereby increasing the flexibility of the usages for this basic biomass – for biogas or other advance biofuels. The mobile unit will consist of a straw lane, a ripper with a capacity of 1 ton/hour, chain conveyors, a silo and a briquetting unit and lane to deliver the briquettes. This unit will need a generator to deliver the energy for the process, but the estimated additional value of the straw should be able to pay off the investment.

In 2014, the project will deliver the model and possibly also the mobile briquetting solution. Hopefully this innovation process will increase the utilization of waste resources for biorefineries in general and thereby contribute to the EU 2020 goals. The project is co-founded by Central Denmark Region and all participating organizations.

This post was written by Knud Tybrik – Agro Business Park A/S (Denmark).

Co-authors: Søren Holm Pedersen – Måbjerg Energy Concept (Denmark); Mogens Sloth Knudsen – CF. Nielsen (Denmark); Michael Støckler, Ida Kjærgaard, Lone Abildgaard – Knowledge Centre for Agriculture, AgroFood Park (Denmark); Henrik Mortensen, Claus Aage Grøn Sørensen – Aarhus University (Denmark).