Balancing supply and demand is a major issue amongst the many challenges associated with bringing renewable energy sources to the market. This is particularly the case with wind and solar. Energy storage systems can herein offer an opportunity to decouple supply and demand, utilizing e.g. biomass as a storage medium in an energy pump scenario.

The current energy supply matrix in Europe is diverse and permits a high level of flexibility in the way power is generated and delivered. This very responsiveness has led to the creation of a pattern of energy use which is intrinsically reliant on the flexibility of the supply. However, as the supply is decarbonised through the increasing use of renewable and nuclear sources, there is significant risk that this flexibility will be lost or at least substantially reduced. As a consequence, governments are actively analysing future energy supply scenarios and identifying ways to try to maintain system flexibility while also delivering carbon reduction targets.

One option to try to maintain flexibility is the integration of local renewable generation sources to enable the optimisation of supplies from solar, wind and bioenergy installations. Local management of supply facilitates a greater degree of responsiveness to local conditions of supply availability and demand, thereby giving back some flexibility. Where power generation sites collaborate at a local level, cooperation rather than competition will characterise energy supply and the opportunities for managing demand through demand side response tools will be increased, since local engagement will tend to be greater.

Storing peak power from sun and wind with Biobatteries

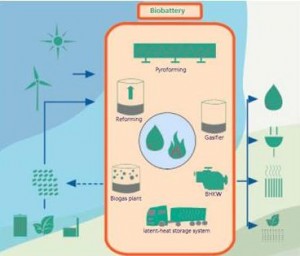

The Biobattery concept from Fraunhofer UMSICHT in Sulzbach-Rosenberg aims at delivering local integrated system solutions, to capture peaks in available power from solar and wind sources and converting and storing this power over periods of varying durations (minutes to days), thereby enabling the delivery of on-demand power compensation.

The Biobattery concept uses a pool of renewable energy technologies, i.e. high and low temperature thermal storage systems, thermochemical biomass processes, e.g. intermediate pyrolysis and gasification, thereby delivering solid, liquid and gaseous energy products which can be stored and used to produce either energy on an on-demand basis, or sold as products for other use. These techniques are be integrated or added to existing installations, such as biogas plants, PV installations and wind turbine facilities, creating a network of energy production and storage units. The makeup of individual networks will depend on the existing infrastructure, the local potential for renewable energy generation and on the nature of local energy demand patterns. By mapping and characterising installations within a region, it would be possible to determine the most efficient way to integrate existing facilities and to identify where new installations should be located to maximise benefit to supply stability and delivered energy cost.

Germany has a capital of over 7500 biogas plants widely distributed across the country which are capable of handling a broad range of biomass and biowaste feedstocks. These facilities could provide the foundation for the development of Biobattery installations. In other countries, wind or solar may provide the foundation round which to build integrated networks.

A Biobattery installation seeks to use peaks in energy supply to add to the energy output from a biogas installation and enable the thermochemical transformation of the more recalcitrant lignin based components of digestion feedstocks. The use of digestate solids as feedstock for intermediate pyrolysis means that the amount of digestate for application to land is reduced to the liquid fraction. This is desirable where there is an oversupply of nitrogenous materials for application to land such as in areas of intensive livestock production, since digestates can be a source of both greenhouse gas emissions and nitrogen losses to water bodies. Hence, the Biobattery not only adds to the flexibility of energy supply and storage, it also increases the energy and financial gain achieved from existing biogas infrastructure, while reducing their environmental impact.

Flexibility of configuration and operation

The strategy employed by the Biobattery is to use external energy sources, namely peaks in electricity supply from the associated wind and solar installations as well as internal heat recovery to dry feedstocks for the pyrolysis stage, power control systems for the intermediate pyrolysis and gasification stages, drive pumps and so on. When necessary, should local wind or solar derived supply be unavailable, the Biobattery installation can buy in low cost electricity from peaks in supply in the electricity grid. An alternative strategy involves the heating of thermal storage units employing phase change materials such as salt hydrates or more traditionally, stone, using solar and wind derived electricity supply and using the heat subsequently for digester heating or feedstock drying, thus avoiding any need to import power from outside the Biobattery network. The heat may also be stored in mobile thermal storage units and transported offsite for use elsewhere.

The pyrolysis unit may be fuelled by a combination of digestate and other materials not appropriate for use as a digester feedstock. The aqueous fraction of the liquid product of intermediate pyrolysis – reformer water, has a high loading of short chain carbon compounds and may be used to enhance biogas yield from the digester. The reformer oil which is produced, as well as the pyrolysis gas, can be used to fuel a combined heat and power (CHP) plant. Alternatively, both may be upgraded in an adjacent gasifier to deliver gas with a high heating value for use in the CHP plant. The solid biochar residue can be used as a soil improver or, together with the reformer water, can be used in hydrogen production.

One of the strengths of the Biobattery concept is the diverse ways in which it can be applied, both in terms of scale, and technology combinations. Optimal energy output is in the range of 150 – 500 kWel. The common feature across different Biobattery installations is the delivery of multiple energy sources, while at the same time optimizing the energy delivery efficiency of each element of the system through combined operation of diverse renewable energy technologies.

Fraunhofer UMSICHT would like to engage with organisations working in the sectors of network management and demand side response system development to build projects to demonstrate the integrated operation of wind, solar and biomass energy production facilities at a local level.

Additional information on the Biobattery concept and expert contacts can be found here.

Text provided by Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT, Germany.