Today in Europe 244 million tons of municipal solid waste (MSW) is generated every year. The biodegradable fraction of MSW (Municipal Solid Waste) ranges between 30-50% wt, accounting for around 100 million tons per year. Currently about 29% of the MSW goes to recycling, 24% to landfilling, 16% to composting and about 27% to incineration. Despite the strong shift from landfilling to recycling of materials such as plastics, metals or glass as well as energy production from the organic fraction by incineration and digestion, there is still a challenge to turn the biodegradable fraction into higher value products than bioenergy.

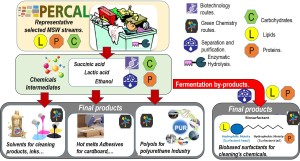

Therefore, the PERCAL project is responding to this challenge by developing new routes for MSW valorisation into intermediate chemical products with huge industrial interest. Those chemicals are succinic acid (SA) with a global potential market of 1,767 million USD by 2025 (Global Succinic Acid Market Analysis & Trends -Industry Forecast to 2025), lactic acid (LA) with 9.8 billion USD of global market by 2025, and ethanol, which has a global potential market forecasted at 115.7 billion USD by 2025.

Using a cascade approach, PERCAL intermediate chemicals will be used as building blocks to manufacture the following products:

- Eco-friendly ethyl lactate, from LA and ethanol by reactive distillation, to be used in cleaning products and inks.

- Lactide based hot-melt adhesives for cardboard and other non-food applications by reactive extrusion.

- Biopolyester-polyols for the production of polyurethanes from bio SA.

- Biosurfactantsby upgrading the residual fraction remaining from bioethanol, lactic acid (LA) and succinic acid (SA) fermentation processes along the PERCAL project.

In the first stage of the project, the main tasks involve the definition of intermediate requirements for the production oftargeted final products, the characterization of representative organic MSW samples, and the first fermentation tests.

One of the main challenges to use the organic fraction of MSW as feedstock for bio-based industries is the complexity and composition variability of the waste, that depend on the waste collection system, geographical location and seasonality. To minimize this problem, PERCAL aims to study and characterize MSW samples coming from different European countries. This characterization will allow the definition and optimisation of the collection, the homogenisation and pre-treatment system for the optimal valorisation of MSW. In the coming months, the objective is to increase the production of potential fermentable sugars from the organic fraction of the MSW up to 85% by enzymatic hydrolysis.

In the meantime, initial fermentation tests were carried out using MSW hydrolysates as feedstocks to produce bioethanol, lactic and succinic acids. The results showed that these bioproducts could be obtained by fermentation in the liquid hydrolysate containing sugars coming from the organic fraction of the MSW. One of the most important findings was that, in principle, no inhibitory effect was noticed during the initial fermentation tests. Therefore, the micro-organisms were able to grow and produce bioethanol, lactic and succinic acid in the MSW hydrolysate at good yields. The next steps in the fermentation area will be to select the most suitable micro-organism strains to produce each chemical intermediate, and optimise the fermentation conditions at laboratory scale, as well as the separation and purification steps from the fermentation broth.

The plan for the next months include the following activities and partners; membrane separation and purification of succinic acid, production of ethyl lactate by reactive distillation, development of hot melt adhesives from lactic acid, investigation of biopolyester-polyols from bio succinic acid, process monitoring and integration, development of surfactants for detergent, and socio-environmental and economic analysis of the project.

More information at www.percal-project.eu

PERCAL project has received funding from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 745828.

The project is coordinated by IMECAL (Spain) and the international consortium includes the following partners: AIMPLAS (technological institute of plastics in Spain), CENER (Spain), AUA(Greece), ATBand COVESTRO (Germany), CMET (Belgium), TBW (Austria), VISUM (Ireland), HAYAT (Turkey) and EXERGY(United Kingdom).

Text by PERCAL Project