Tar and tar related problems are still major obstacles for the development and implementation of biomass gasification technologies. Aromatic and polycyclic aromatic hydrocarbons (PAH) are by-products in most high temperature thermochemical conversion processes. They lower the efficiency of these processes and form tarry deposits when the gases are cooled and vapours begin to condense. For an effective management of tar, efficient measurement tools are necessary to monitor PAH composition and load of the product gas. Measurement should be sufficiently fast to allow for process control, in order to minimize the formation of these compounds in the reactor. Up to now, no easy-to-use and reliable tool with a sufficiently low dead time has been available for tar monitoring.

LED technology for industrial applications

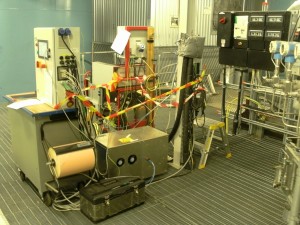

A new online tar measurement technique developed by Technische Universität Berlin is based on Light Emitting Diodes (LED) for Fluorescence Spectroscopy. The basic principle behind the measurement technique is simple. By detecting the emitted light from the analytes (tar forming aromatic species in the gas) with a spectrometer, information about the total amount and some information about the molecular size distribution can be obtained. Light emitting diodes have several advantages over lasers when it comes to industrial applications. Besides being more stable and reliable especially in a rough environment they are also much cheaper. It is possible to combine multiple diodes with different wavelengths in an array to take advantage of the diverse absorption-emission behaviour of different PAHs.

A technical breakthrough

At the end of 2016, this innovative online tar measurement technique was installed and tested in the 20 MW GoBiGas plant in Gothenburg, in the framework of the three-year project BioProGReSs (Biomass Product Gas Reforming Solutions). GobiGas is the world’s first industrial scale plant for production of biomethane through gasification and methanation of biomass, also called bioSNG. The plant is based on indirect gasification and the produced biomethane is injected into the high pressure natural gas grid in Gothenburg. At this stage, it is possible to measure changes in the level of the detected tars and also if there is a shift towards heavier or lighter tars during operation. Ingemar Gunnarsson, Development engineer at Gothenburg Energy and no friend of big words stated that “It looks very promising” regarding the industrial use. Indeed, this is a technical breakthrough that has potential to revolutionize monitoring and control of biomass gasification processes worldwide.

About BioProGReSs

BioProGReSs is an acronym for Biomass Product Gas Reforming Solutions. The aims of the industry led and multidisciplinary project are among others to reduce the investment and operating cost of the syngas cleaning and increase the yield of biomethane from the gasified biomass. The project partners are Gothenburg Energy (coordinator), Chalmers University of Technology, Technische Universität Berlin and Renewable Energy Technology International AB. The three year project (October 2014- September 2017) is supported by the Swedish Energy Agency and FNR, Germany. The support is made possible by industrial co-financing in the form of access to the Chalmers gasifier and the GoBiGas plant for testing, development and evaluation of new technologies for syngas cleaning.

The project has been granted funding from the European Union’s Seventh programme for research, technological development and demonstration under grant agreement 321477 and from the German Federal Ministry of Food and Agriculture (FKZ 22401814), for development and demonstration of advanced syngas cleaning. The BioProGReSs project is part of the European initiative, Bioenergy Sustaining the Future (BESTF), http://eranetbestf.net/home/.

This post is based on an edited version of a text provided by Jörgen Held, Renewable Energy Technology International AB, BioProGReSs communication manager.