Fast pyrolysis bio-oil is a renewable liquid fuel which can replace fossil fuels in energy production. In Finland there are currently a few ongoing projects concerning the production of pyrolysis oil. As a new product, transportation requirements and conditions must be taken under consideration.

Pyrolysis oil is a liquid biofuel produced e.g. from biomass or other raw material that contain carbon. Pyrolysis oil is produced in a pyrolyzers which can be integrated into a CHP power plant or it can be a stand-alone unit. Conventional CHP boilers can utilize uncondensed vapors and coal residues which will increase the total efficiency of pyrolysis oil plants and CHP-plant integration. An integrated fuel supply and handling system is also beneficial for both processes.

In Finland there are currently a few ongoing projects concerning the production of pyrolysis oil from biomass. Production capacity of one pyrolysis oil production plant in Finland could be up to 100 000 tons per annum. Pyrolysis oil is a versatile fuel because it can replace heavy fuel oil (HFO) in heat and electricity production. In the future pyrolysis oil may be also one alternative fuel for shipping and it can be refined for transport fuel and used as chemical.

Pyrolysis oil’s lower heating value is about half of fossil oils (LFO and HFO) heating value. Pyrolysis oil is generally acidic, unstable at high temperatures or over long storage periods, highly polar and mainly non-volatile containing a large amount of chemically dissolved of emulsified water. Due to acidity pyrolysis oil will be classified as dangerous goods in road, railway and waterway transport.

Solutions for transportation

Feasible possibilities for pyrolysis oil transportation in Finland are road, railway and waterway transports. However pyrolysis oil has never been transported in large-scale in Finland. As a liquid pyrolysis oil must be transported in tanks or in tank containers. Tank trucks and tank wagons are currently the most common methods for road and railway transports. Waterway transport has mainly used for import and export and inland waterways for raw wood and bulk material (e.g. coal) transports.

When transporting dangerous goods, labeling is always required and it is also required for pyrolysis oil road, railway and waterway transport. In labeling (Figure 1.) the lower UN number 3265 stands for “Corrosive liquid, acidic, organic, n.o.s.” and 80 stands for corrosiveness (8) without any secondary hazard (0). For waterway transport pyrolysis oil will also need IMO classifications.

Pyrolysis oil requires specified equipment in loading, unloading and handling. All surfaces in contact with the product must be acid proof material. Suitable materials are acid proof steel such as AISI 316L or some polymers such as PTFE (Teflon). Suitable gasket materials could be e.g. Viton and Teflon, which are commonly used e.g. for sulfuric acid. Acidic products are already transported widely and suitable transport equipment exists. However suitable equipment for road, railway and also waterway are currently in some kind of use so either new investments are needed or equipment may free from their current duties.

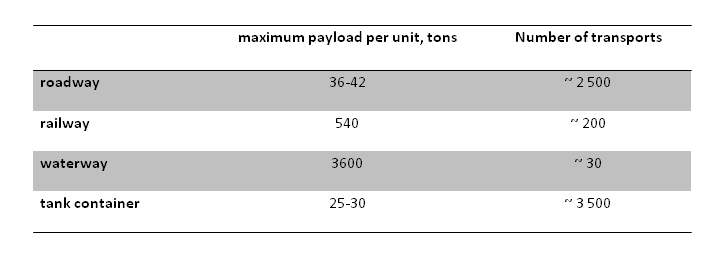

In Table I different transportation methods are illustrated , for typical unit sizes and indicative annual transportation flows for a volume of 100 000 tons per annum. In calculation, hypothesis is that all production is transported regularly with single transportation method. Usually in practice the logistical chain could consist of combination of different alternatives. For railway transport it is estimated that one train consists of ten chemical wagons and tank containers are transported by road with semi-trailer. Maximum payloads per unit can vary between different European countries.

Suitable transportation method is always closely related to production sites and end-users facilities, existing transport connections and annual production volumes. Transport distance is also very important factor and the location of production plant determines suitable options and conditions for transportation. If production volumes are larger, producers could invest e.g. on new railway connections and wagon capacity.

Roadways railways and waterways

Road transportation with truck and full-trailer combination is currently the most cost-effective and flexible option if no railway connection or deep-water harbor exists in production plant. Main advantages for road transport are constant transportation flow from production to end-users and the most extensive coverage. Advantages for railway and waterway transports are larger unit size per one transport. Railway transportation would be good option for straight long-distance domestic routes from production plant to end-user. If extra loading and unloading are needed the profitability of railway transport could decrease. Waterway transport with chemical tankers is the best method for large-scale exportation when size of one load is at least 3 000 m³. However railway and waterway transports have the most significant limitations in Finland. Railway network in Finland is quite extensive but production plant needs to be situated along it to make railway transport practical. Waterway transportation also needs chemical ports and sufficient storage capacity to operate. For these reasons truck transport is often needed in some part of logistical chain for railway and waterway transport in Finland.

Pyrolysis oil is a new fuel product in European markets and it will surely create employment in raw material supply, oil production and in end product transportation. When transporting pyrolysis oil e.g. with trucks, hundreds of transportations are needed annually in Finland if production volume per plant could be as high as 100 000 tons per annum. These high volumes could offer constant business opportunities for operators.

The requirements and classification for pyrolysis oil transportation are needed because large-scale production should be commercialized in Finland in next few years. Pyrolysis oil will be classified as dangerous goods in transportation and it can be transported with all conventional transportation methods. Different methods have limitations that must be taken into consideration as well as national legislations. All challenges concerning the transportation are solvable and more dangerous goods are transported all the time in European roads, railways and waterways.

Written by Mika Laihanen – Lappeenranta University of Technology, Finland