The project HyFlexFuel is focused on the development of a production chain for sustainable liquid fuels based on hydrothermal liquefaction of various biomass feedstocks.

Background and objectives

The collaborative Research and Innovation Action (RIA) HyFlexFuel works on advancing the complete production chain for sustainable drop-in fuel on the basis of hydrothermal liquefaction (HTL) as key conversion technology. HTL offers the possibility to convert essentially any type of biogenic material into liquid fuels without the requirement of prior energy-intensive drying.

HyFlexFuel aims to develop each process steps of HTL-based fuel production and to demonstrate their viability under relevant operational conditions. This includes the upgrading of the intermediate product biocrude to final fuels and the valorisation of residual process streams.

Specifically, the HyFlexFuel partners will:

- demonstrate compatibility of HTL-based fuels production with a diverse biomass feedstock portfolio, including algae and waste streams, such as sewage sludge;

- increase energy and carbon efficiency of HTL through improved heat integration and product recovery;

- valorise organic and inorganic components in residual process streams;

- upgrade biocrude from HTL conversion by catalytic hydrotreatment into fuel products and demonstrate their drop-in capability;

- assess technical, socio-economic and environmental performance potentials.

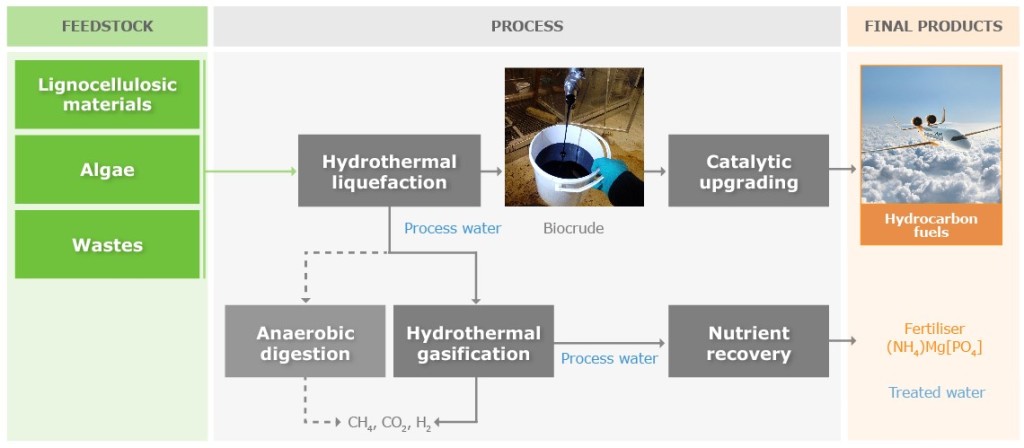

The HyFlexFuel process

In HyFlexFuel, a broad range of biomass feedstocks, such as sewage sludge, microalgae and the energy grass miscanthus, is processed via hydrothermal liquefaction (HTL). In the HTL step, feedstocks are used as aqueous slurries and converted at temperatures of around 350 °C and pressures of about 200 bar. In principle, this process resembles the natural formation of crude oil from biomass in past geologic era. The resulting biocrude, a viscous black oil phase, is catalytically upgraded in a high-pressure hydrogen atmosphere (hydrotreating) and converted into a mixture of hydrocarbons. Through this process, undesired elements, such as oxygen and nitrogen, can be effectively removed. Moreover, conditions can be tuned to increase the production of the desired fuel fractions (e.g. gasoline, diesel, jet fuel). Liquid drop-in fuels are obtained by means of distillation from the upgraded biocrude.

The remaining aqueous phase from the HTL step contains substantial quantities of organic compounds that have to be valorised in order to facilitate an economically feasible process. Therefore, the aqueous phase is treated via catalytic hydrothermal gasification (cHTG) under supercritical conditions to produce methane and hydrogen. The high-energy gas can be used for on-site production of electricity and/or heat. As alternative technology option, anaerobic digestion is applied in HyFlexFuel for methane generation from the aqueous phase.

Finally, inorganic salts containing nitrogen and phosphorus are recovered from HTL solids and the aqueous phase in the form of marketable fertilisers.

Results

In the first half-year of the project, an initial HTL campaign was successfully conducted using the pilot-scale research plant of Aarhus University that allows continuous processing in an industrially relevant environment. Sewage sludge, the microalgae Spirulina and Miscanthus were used as starting material. 60 L of slurry per hour were fed into the reactor, yielding overall >10 kg of biocrude and >200 L of aqueous phase from each feedstock – a promising result. This enabled the supply of sufficient sample volumes to all project partners for further analysis and conversion experiments. Preliminary activities have been also performed by Aalborg University in the field of biocrude hydrotreating, achieving very high or even complete deoxygenation. These results are promising in view of the production of drop-in fuels. In the future course of HyFlexFuel, larger campaigns for HTL and all other process steps are scheduled with the aim to demonstrate the entire production chain in relevant operational environments.

Facts

HyFlexFuel combines the expertise of ten European partners from academia and industry: Bauhaus Luftfahrt e.V., Aarhus Universitet, Aalborg Universitet, Paul Scherrer Institut, Deutsches Biomasseforschungszentrum, Universität Hohenheim, OWS nv, Eni S.p.A., Haldor Topøe AS, Arttic. The project was kicked off in October 2017 and will be completed in September 2021.

HyFlexFuel (Hydrothermal Liquefaction: Enhanced performance and feedstock flexibility for efficient biofuel production) has received funding (EUR 5.04 million) from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 764734.

HyFlexFuel (Hydrothermal Liquefaction: Enhanced performance and feedstock flexibility for efficient biofuel production) has received funding (EUR 5.04 million) from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 764734.

For further information, visit HyFlexFuel website.

This article is by Dr. Arne Roth, Bauhaus Luftfahrt e. V.